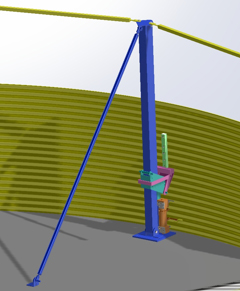

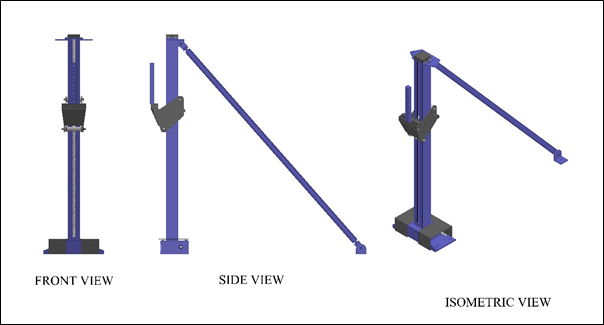

Mechanical Screw Jack for Steel Bolted Tank & Grain Silo

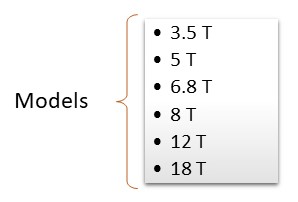

We manufacture different models as below:

Different types of tanks can be erected using our Mechanical Tank Jacking Equipment:

- Bolted Silo tank

- GLS Tank

- GFS Tank

It can be used for:

- Fabrication of Tanks

- Dismantling of Tanks

- Increase the height of Tanks

- Decrease the height of Tanks

- Relocate Tanks

- Replace Tank Bottoms

- Repair Tank Bottoms

Hydraulic telescopic jacks for steel bolted Tank & Grain Silo

Astha Group of a company manufactures and rents hydraulic telescopic jacks of different models suitable to lift up to 2500 mm. These jacks are used in the erection of bolted or welded tanks for storing water or other bulk liquids or powders. Our standard jack is a three-stage jack, providing exceptionally even lifting.

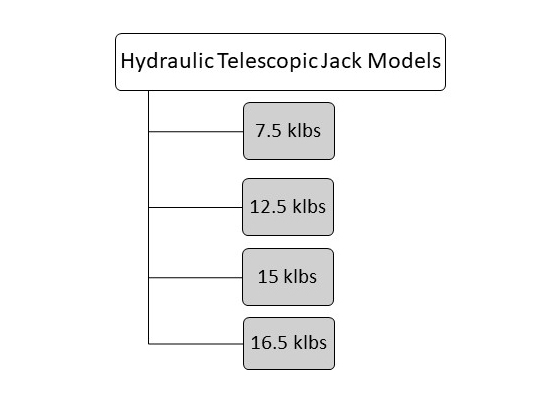

Below shows the Models for the Hydraulic Telescopic Jacks

Hydraulic Lifting Jack Model

The time for lifting a shell plate up to 2.5 meters in height is as follows:

- Using double-acting jacks - 45minutes

- Using single-acting jacks - 3-3.5 hours

Double Acting Jacks work 5 times faster than Single Acting Jacks

|

Model / Description |

AIEIPL-HTJE-12MT-SA |

AIEIPL-HTJE-12MT-DA |

AIEIPLAIEIPL-HTJE-18MT-DA |

AIEIPL-HTJE-25MT-DA |

|---|---|---|---|---|

|

Working Capacity (Metric tons) |

12 |

12 |

18 |

25 |

|

Testing load (metric tons) |

18 |

18 |

27 |

37.5 |

|

Standard Arc Distance between Jacks (m) |

2 to 3 (as per site requirements) |

|||

|

Max. Shell Plate Lifting Height (m) |

2.5 or 3 or more (as per client requirements) |

|||

|

Min. Shell Plate Lifting Height (m) |

0.80 |

|||

|

Min. Safe Bearing capacity below Trestle Plate (N/cm2) |

1.45 |

|||

|

Plate Thickness range (mm) |

6 and above |

|||

|

Unitary Climb (mm/stroke) |

100 |

|||

|

Time per stroke (minutes) |

10 |

1 to 1.55 |

||

|

Working Pressure (Kg/cm2) |

120 |

142 |

160 |

|

|

Piston Retracting System |

Spring |

Hydraulic Pressure |

||

|

Trestle Retractable System to allow Internal welds using an Automatic Girth Welding Machine |

No |

No |

No |

No |

|

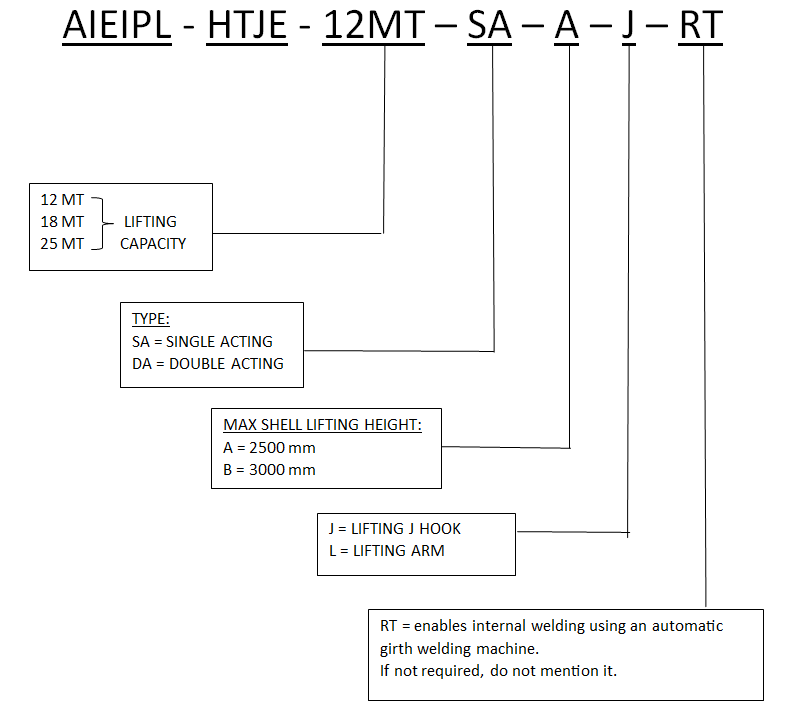

Model No. (also order example) |

|

|---|---|

|

Model No. |

AIEIPL- HTJE-12MT-SA = Single Acting Jack 12-ton capacity AIEIPL- HTJE-12MT-DA = Double Acting Jack 12-ton capacity AIEIPL- HTJE-18MT-DA = Double Acting Jack 18-ton capacity AIEIPL- HTJE-25MT-DA = Double Acting Jack 25-ton capacity |

|

Maximum shell lifting height |

A = 2500 mm B = 3000 mm |

|

Type of Contact with shell plate |

J = Lifting J-hook: no welding of lifting cleats to tank shell plate. L = Lifting Non-Welded Arm: cleats to be welded to the tank shell plate. |

|

Retractable system |

RT = enables internal welding using an automatic girth welding machine. |

|

Example: AIEIPL-HTJE-12MT-DA-A-J-RT: Double acting jack 12-ton capacity suitable for 2500 mm width shell plate with lifting J-hook and with retractable arrangement. |

|

Hydraulic Jack for Steel Bolted Tank & Grain Silo

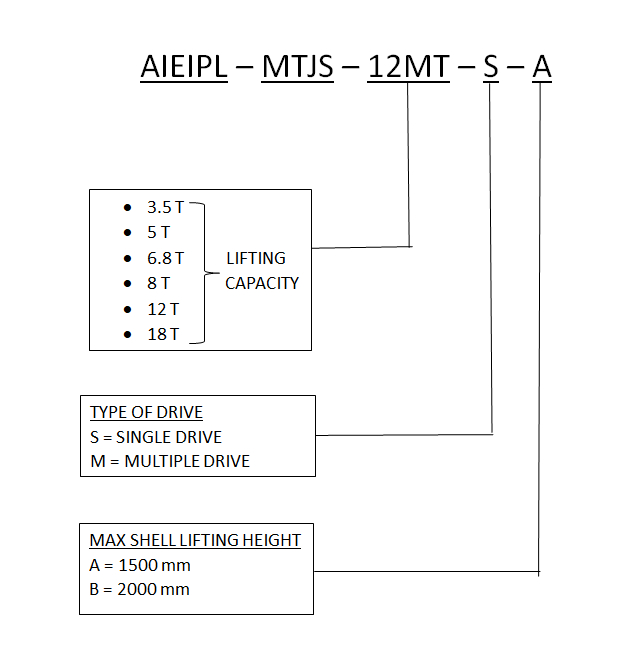

Our company specializes in the production of hydraulic jacks that are designed to facilitate the erection of bolted tanks with the assistance of a bucket assembly. Our hydraulic jacks are engineered to provide reliable and efficient support during the construction process, ensuring that your bolted tanks are erected safely and securely. With our state-of-the-art hydraulic jacks, you can rest assured that your construction project will meet the highest standards of quality and safety. Our company produces a range of models, including the 6.8 MT & 12 MT.